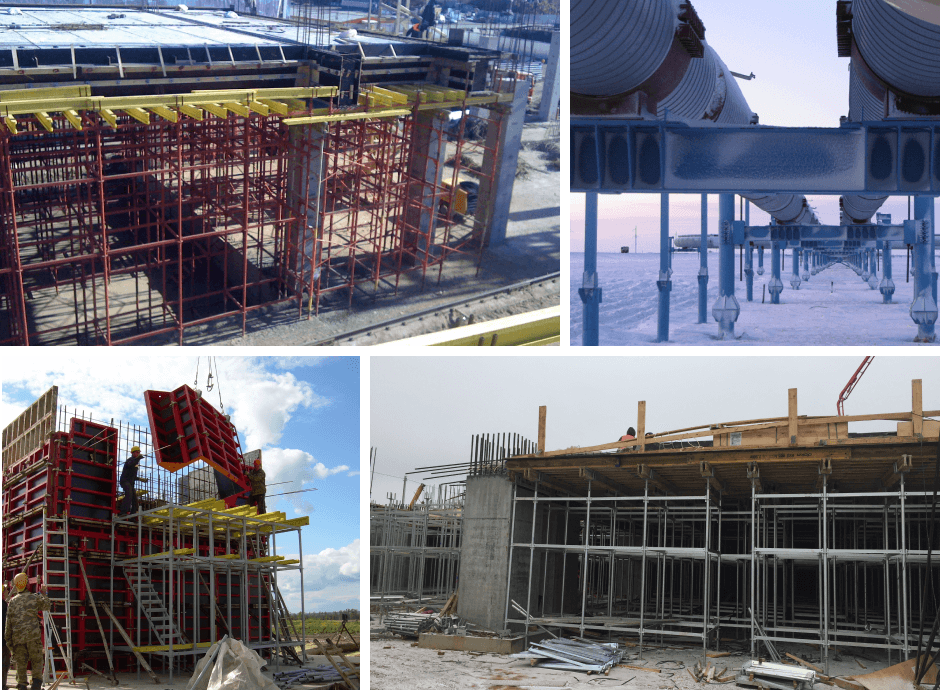

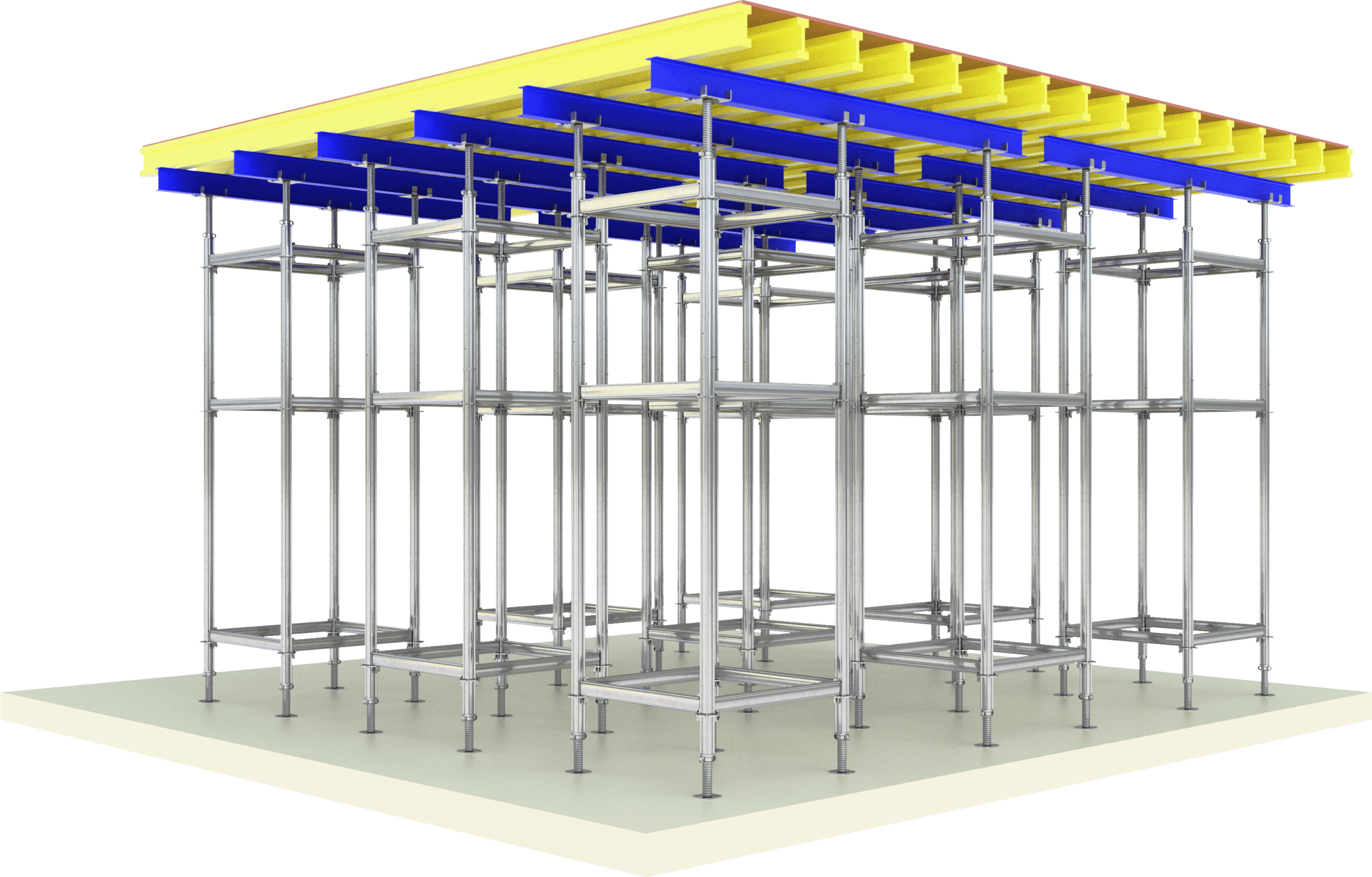

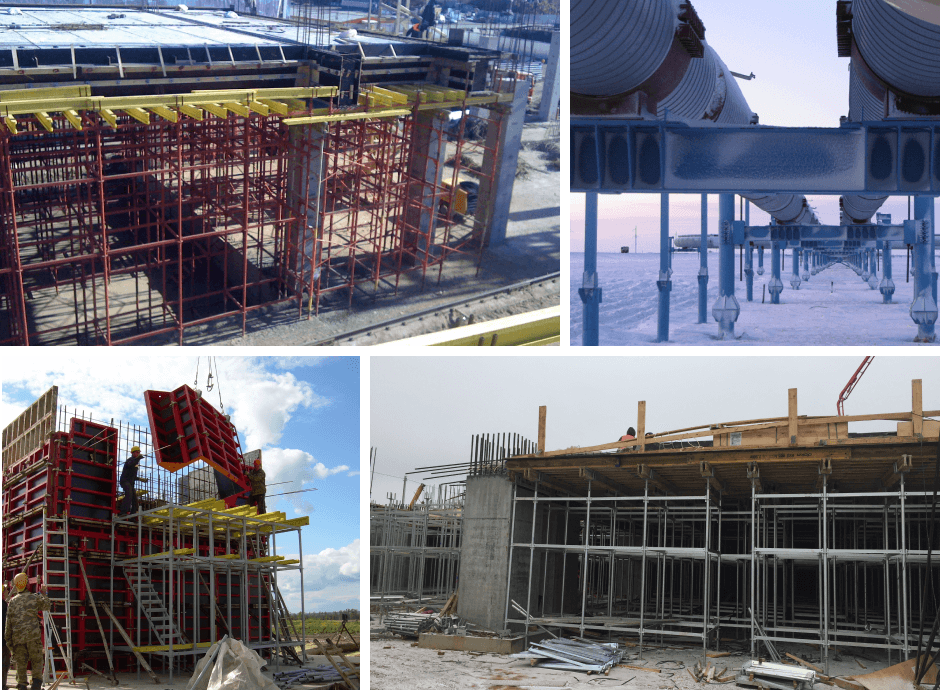

We have been helping hundreds of companies to build sophisticated and High-Tech projects in Russia and CIS countries during more than 20 years. They are nuclear power plants, aeroports, stadiums, MKAD exits, elevators and metro stations.

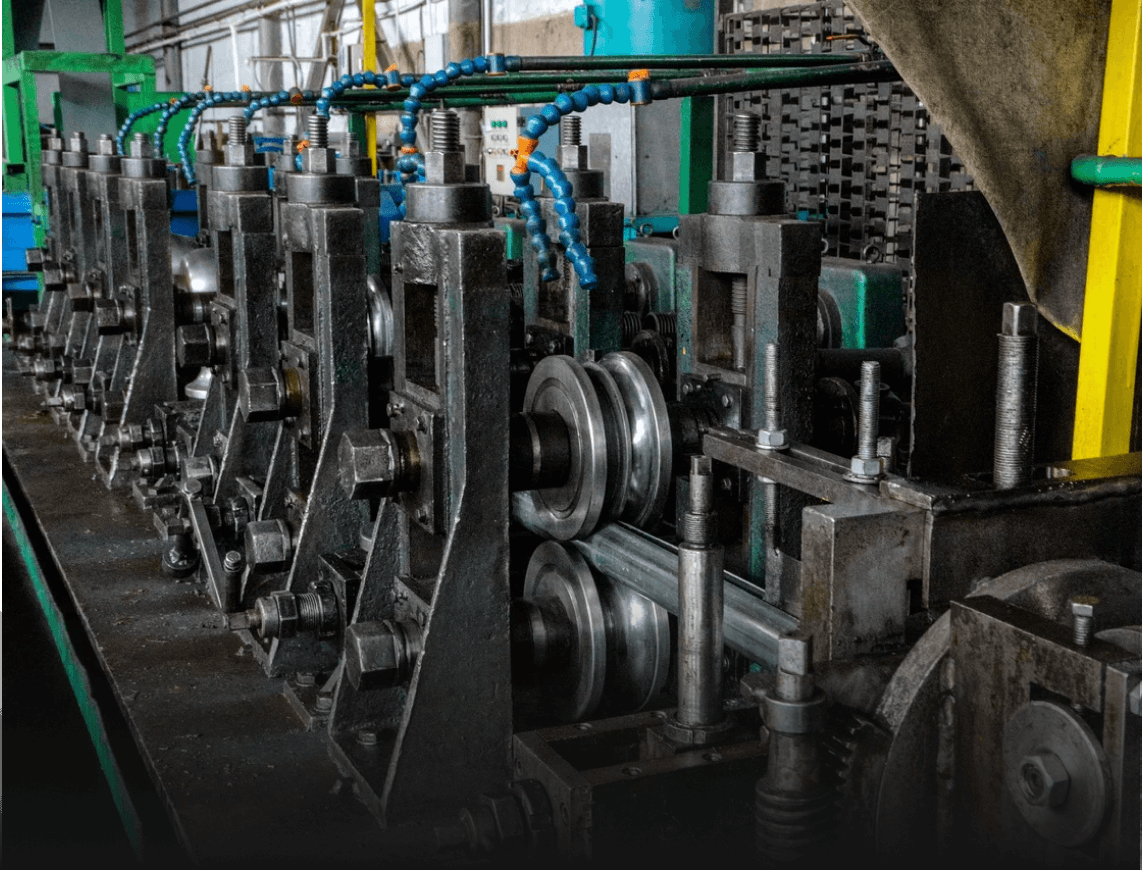

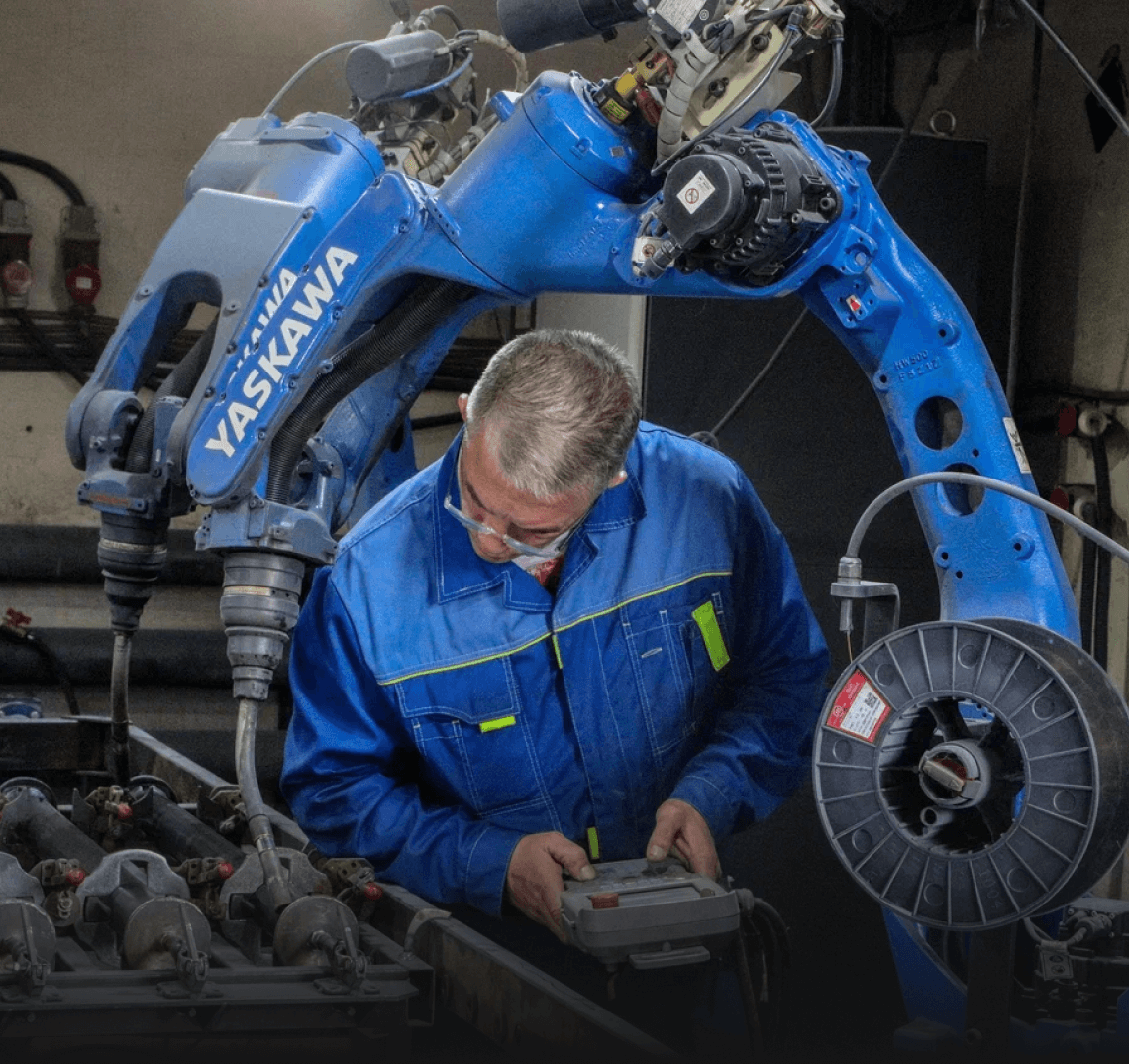

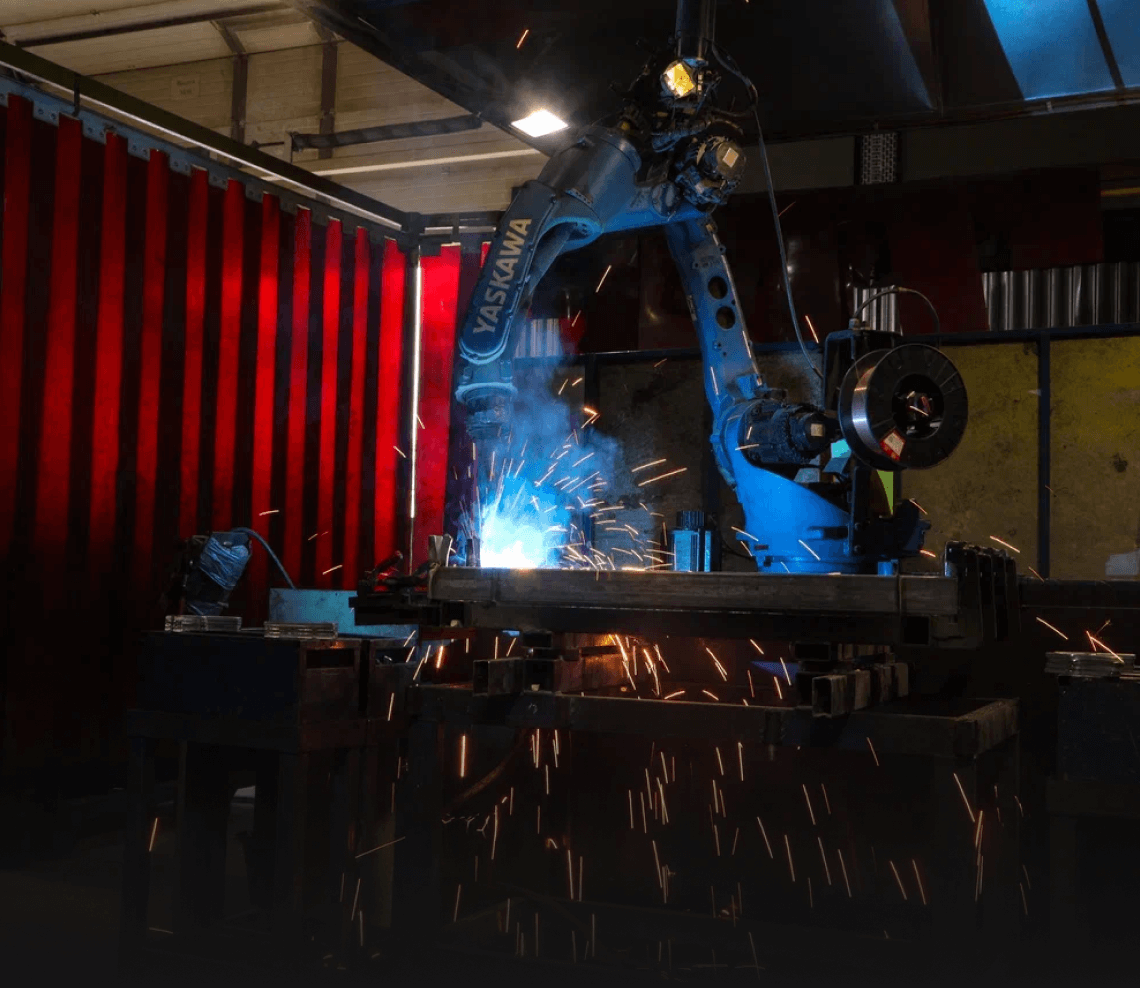

Our production technologies have reached a new and innovative level thanks to high precision equipment and the qualified staff.

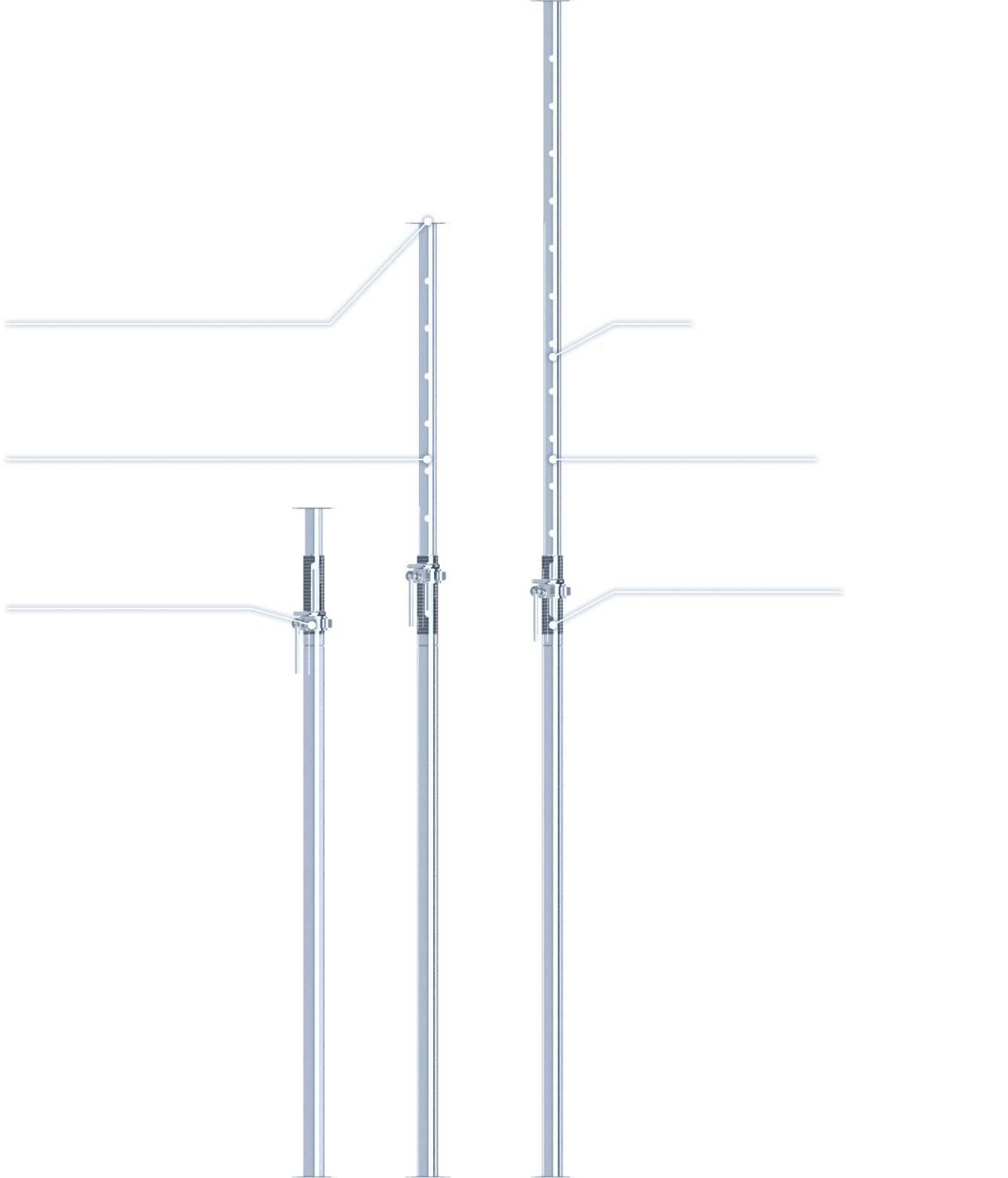

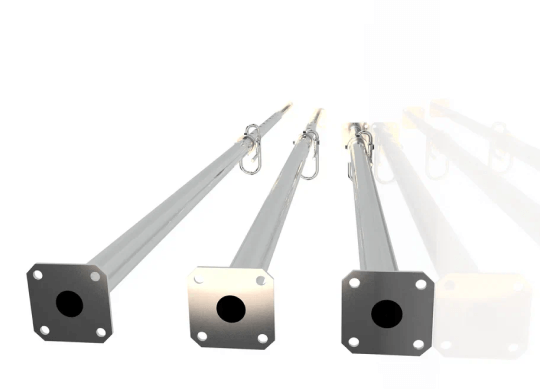

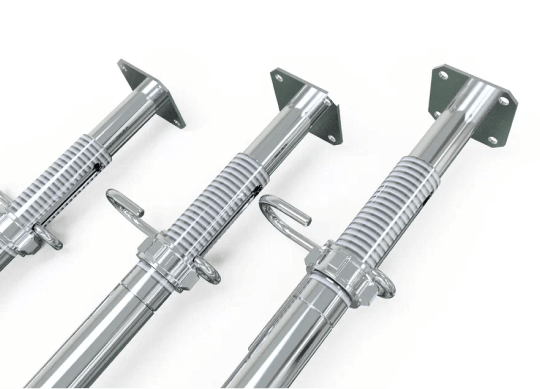

2001 HSI LLC – a company selling building jacks

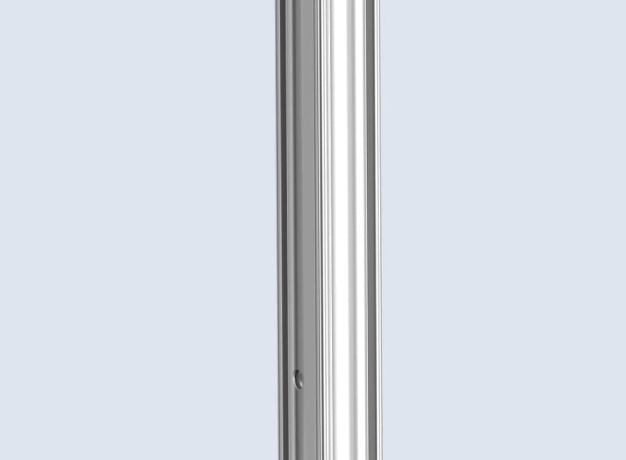

2003 We launched our own production of building jacks

2004 We bought our own production sites

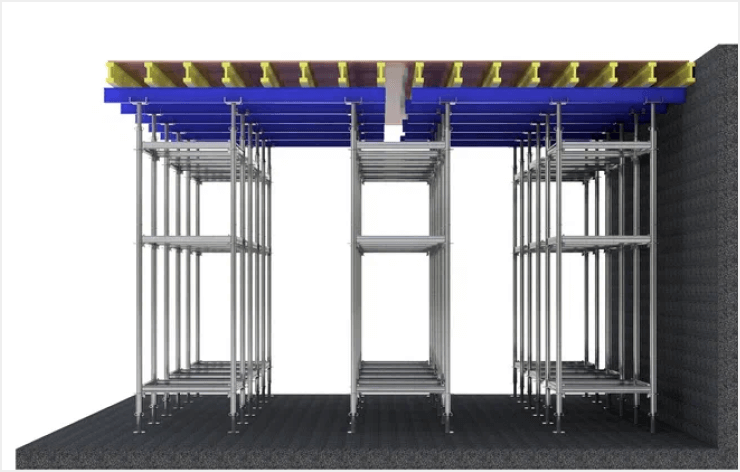

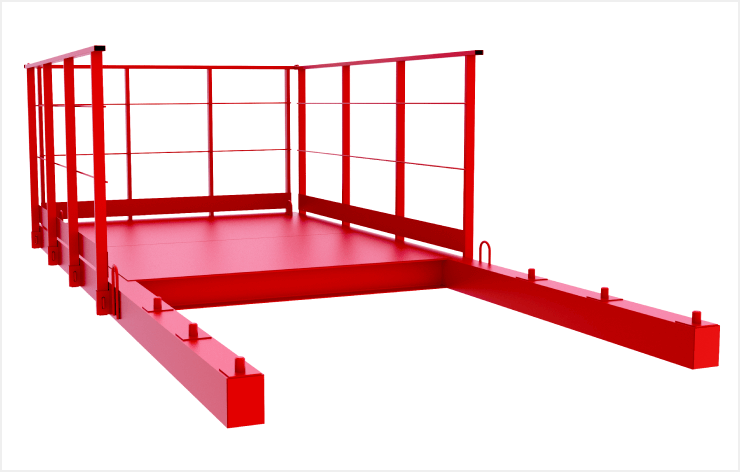

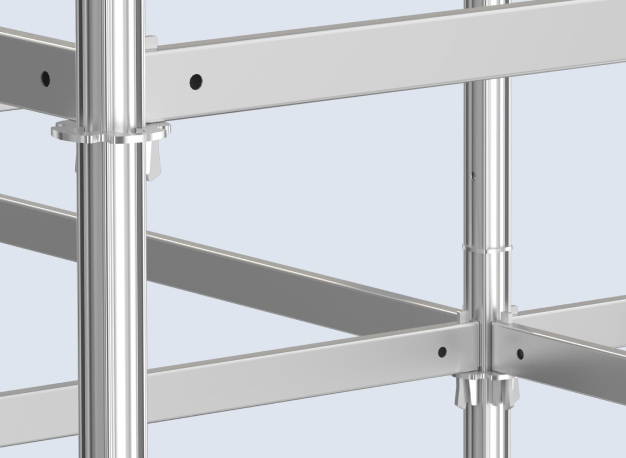

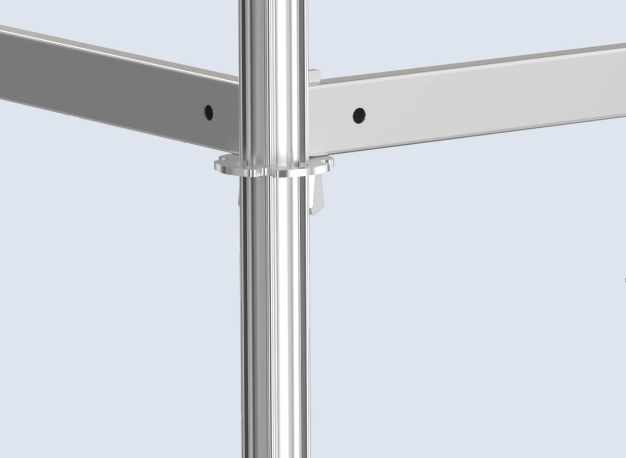

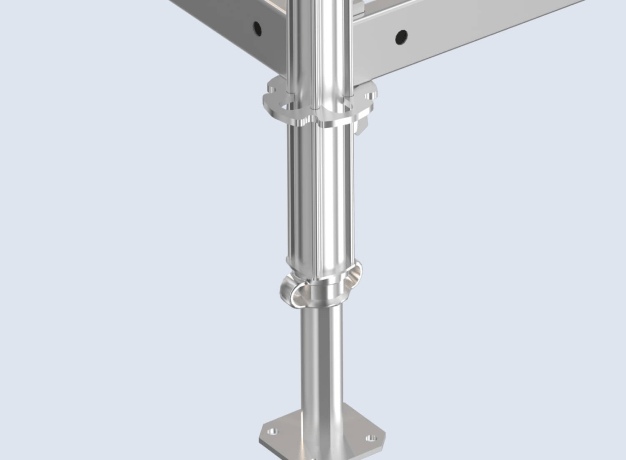

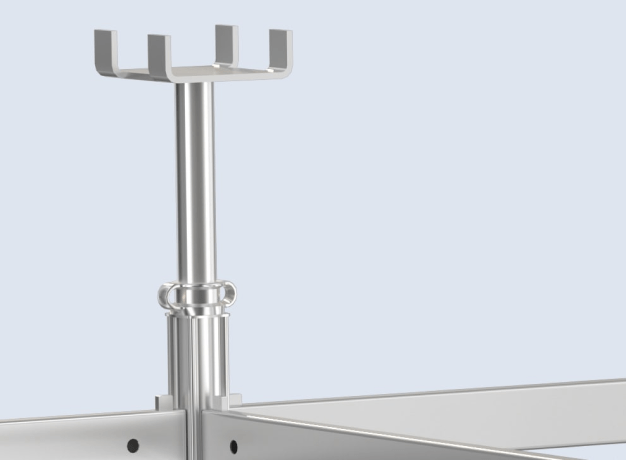

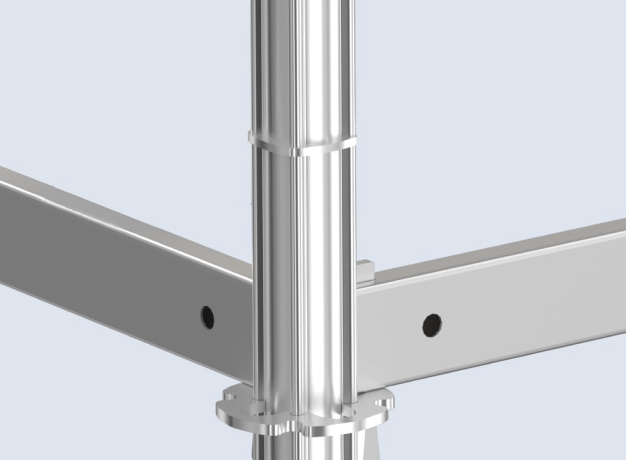

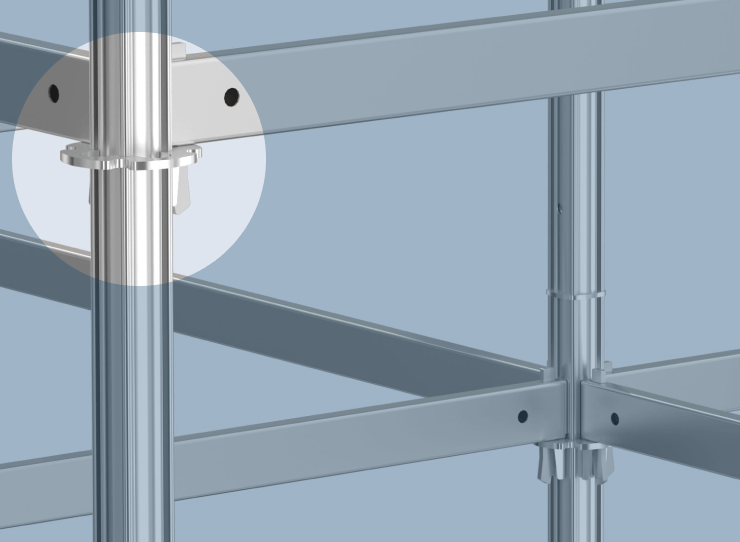

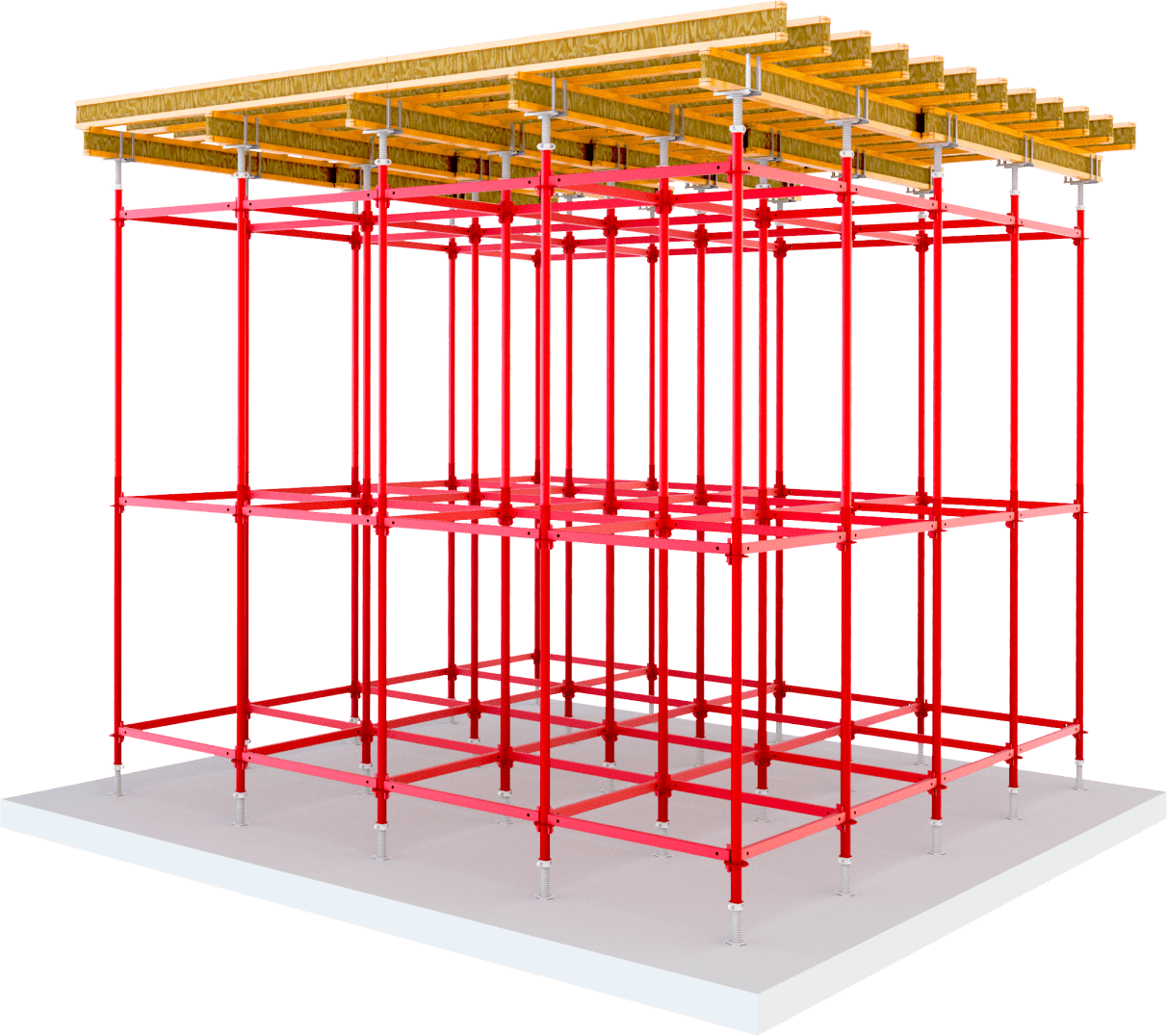

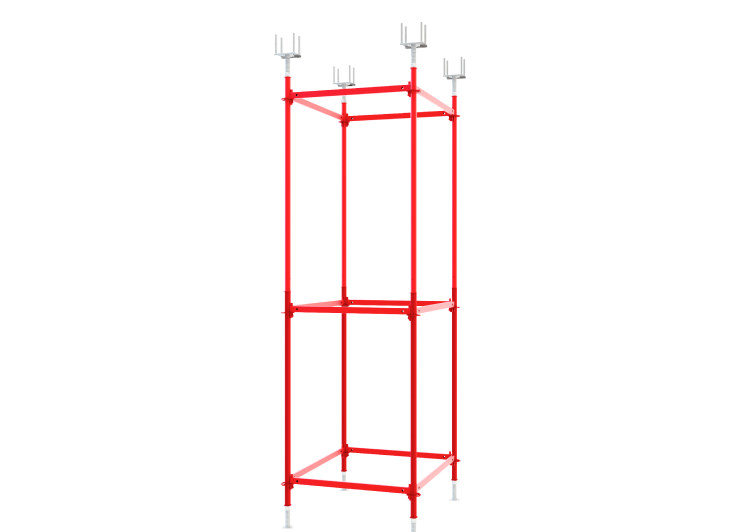

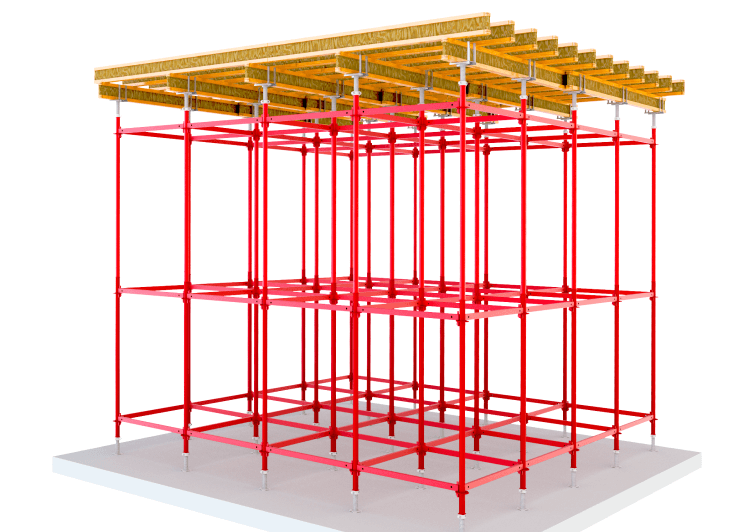

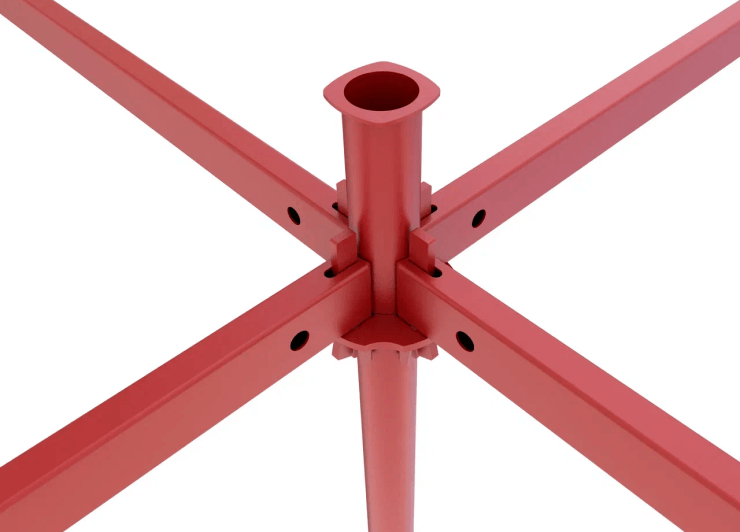

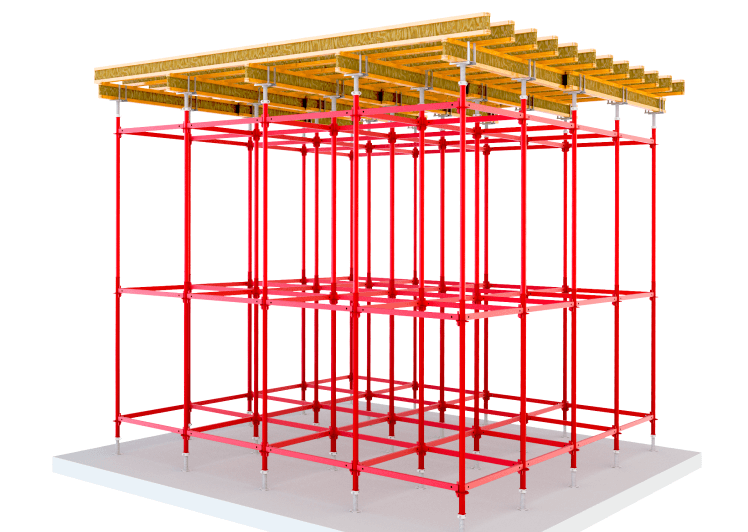

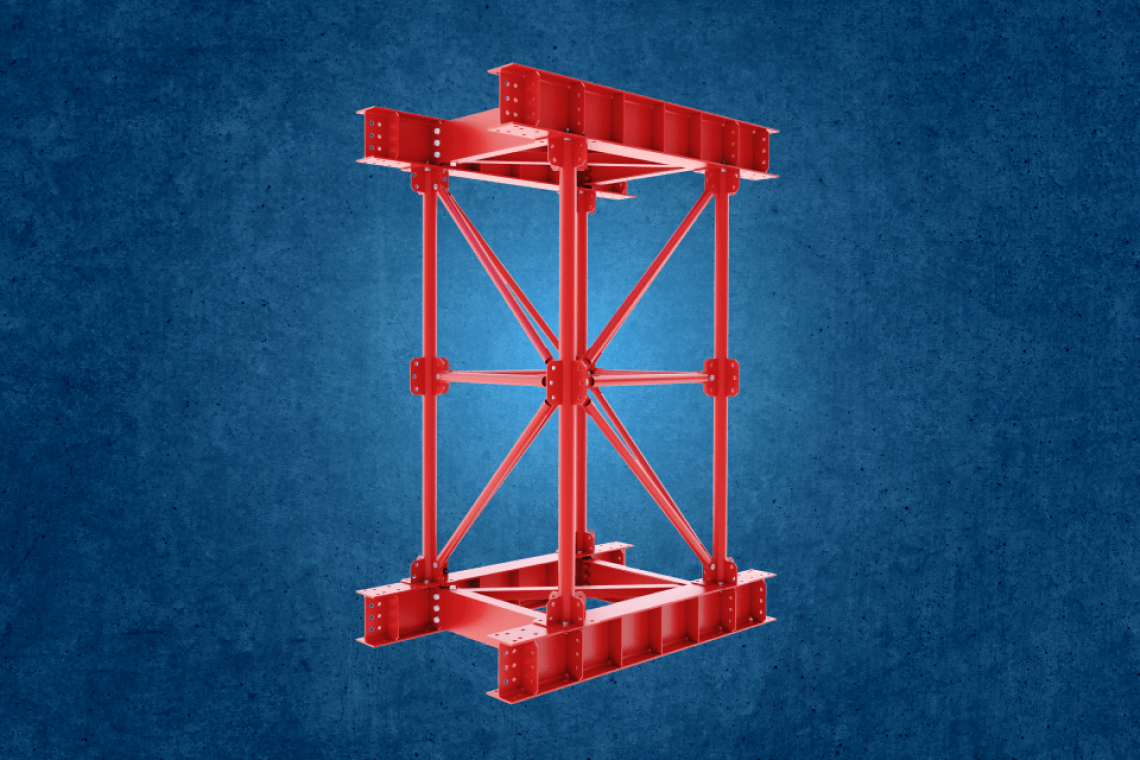

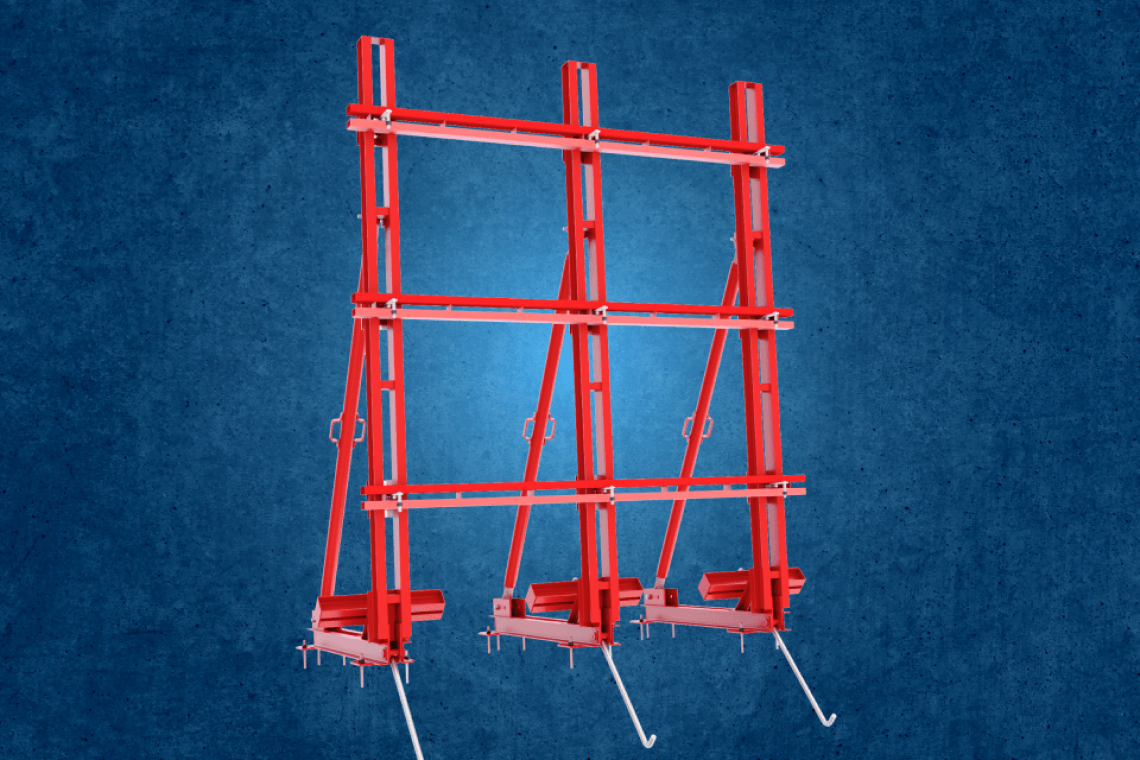

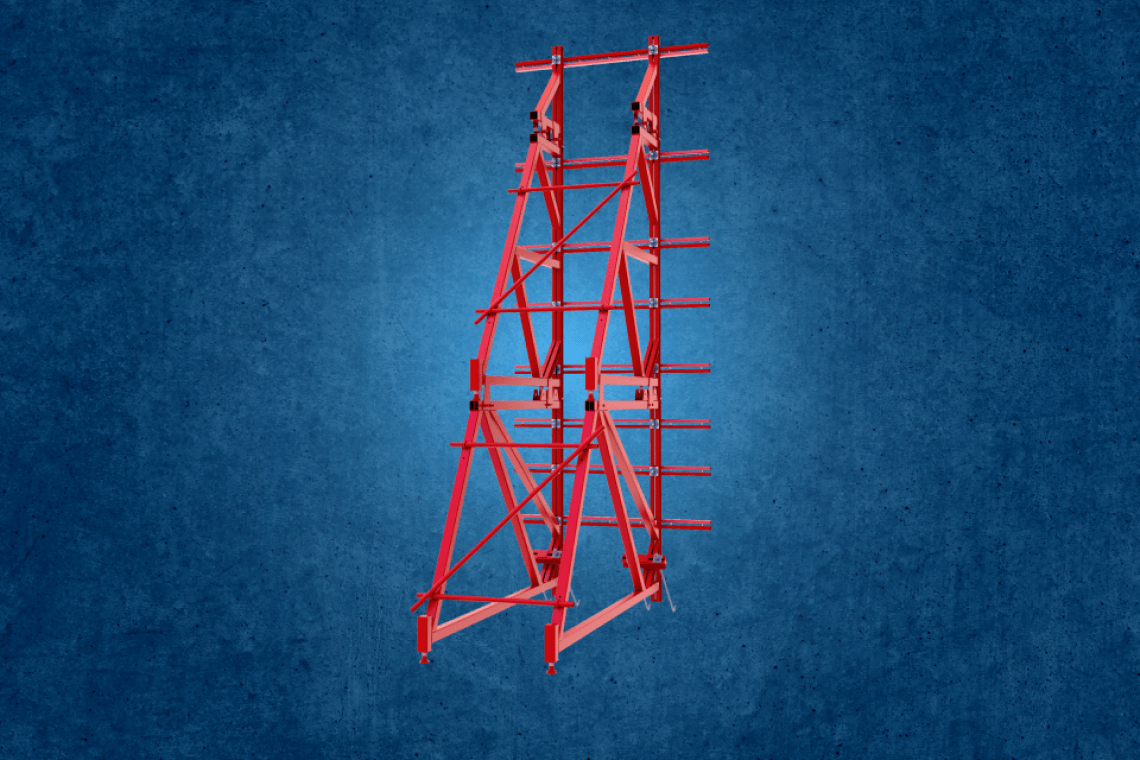

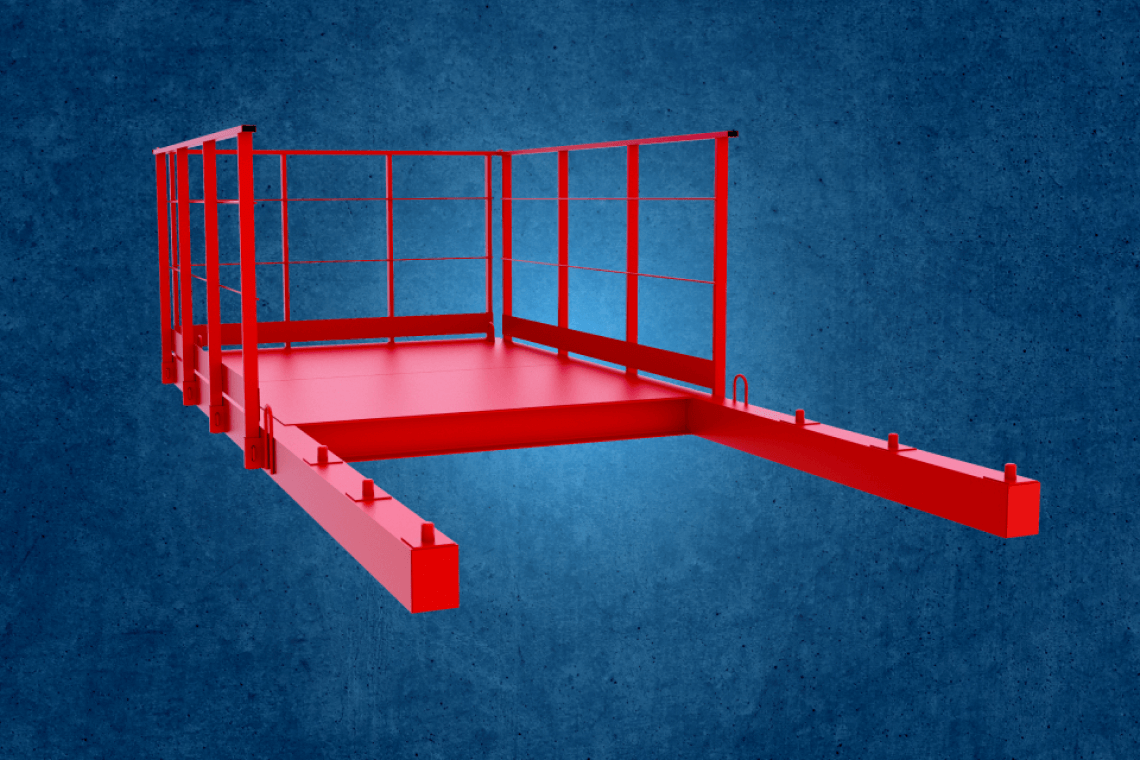

2005 We launched scaffolding and formwork production on the basis of ringlocks

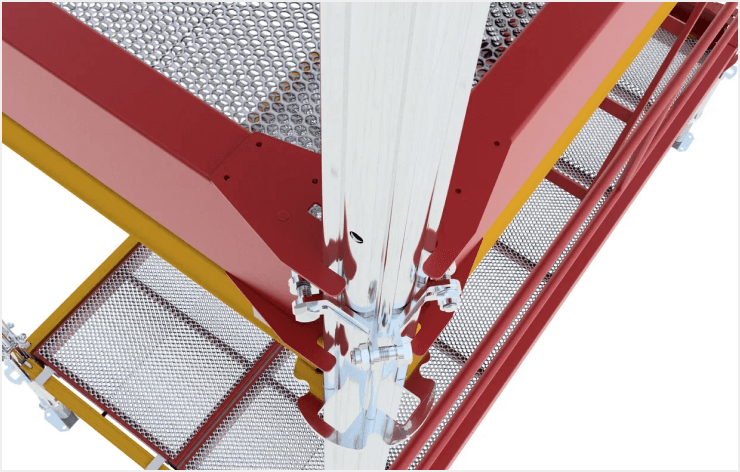

2007 We got the patient for the ringlock

2008 Bazis Holding LLC registration

2010 Production capacity was increased two times

2014 Automatic galvanic coating and tube-rolling lines werу launched

2015 Cooperation with PERI, the leader of the world formwork market

2018 We have bought and began to use new equipment such as laser cutting and processing machines, welding machines, manipulators

2020 Development of the ТМ WESKER unique profile and getting the patient